Categories

New products

-

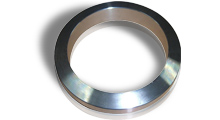

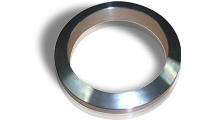

Lens Ring Joint Gasket

China Lens Ring Joint Gasket manufacturer,supply Lens Ring Joint Gasket to your requirements. More quality Lens Ring Joint Gasket product info of Kaxite click here.

-

Double Jacket Gasket

China Double Jacket Gasket manufacturer,supply Double Jacket Gasket to your requirements. More quality Double Jacket Gasket product info of Kaxite click here.

-

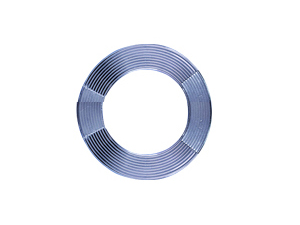

Corrugated Gaskets

China Corrugated Gaskets manufacturer,supply Corrugated Gaskets to your requirements. More quality Corrugated Gaskets product info of Kaxite click here.

-

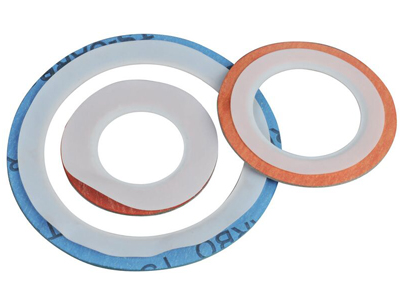

PTFE Envelope Gasket

China PTFE Envelope Gasket manufacturer,supply PTFE Envelope Gasket to your requirements. More quality PTFE Envelope Gasket product info of Kaxite click here.

-

CGFO Packing

China CGFO Packing manufacturer,supply CGFO Packing to your requirements. More quality CGFO Packing product info of Kaxite click here.

Lens Ring Joint Gaskets

> Lens ring joint used in higher pressure than 3,000 lbs. > These gaskets had been used on pipe flanges in synthesizing line.

Lens ring

Metal lens gasketHigh pressure pipe connection, the widely used lens gasket sealing structure.Lens gasket seal face were spherical, contact with the pipeline cone sealing faces, the initial state for a loop.Under the pre-tightening force, lens pad in contact produce plastic deformation, the loop into a ring, good sealing performance.Due to the contact surface is made up of spherical and cant naturally formed, in a gasket is easy.Lens gasket seal belongs to forced sealing, sealing surface for spherical surface and conical surface contact, easy appear indentation, poor interchangeability of parts.In addition, the gasket manufacturing cost is higher, processing also more difficult.

Metal lens gasket performance characteristics:

1, high temperature resistant, resistant to high pressure, suitable for high pressure flange;2, reliable sealing persistent;

3, to adapt to the working conditions of pressure and temperature fluctuations;

Metal lens gasket application scope: general machinery industry in our country the current Angle type high pressure valve end flange, USES the lens gasket seal, apply to the nominal pressure of 16.0 ~ 32.0 Mpa.Nominal diameter is 3 ~ 200 mm;Use temperature was minus 30 ~ 200 oC, often used for sealing of high-pressure hydrogen acid medium.

Metal ring gasket first comes from the United States, in the 1920 s, the first to use in boiler, then used for manhole cover, autoclave other Windows sealed, later in the oil production and refining industry particularly valued.With the increase of temperature and pressure of the steam power plant, metal ring gasket have been used more and more widely.

Metal lens gasket main structural forms:

| material | Maximum hardness | mark | oC | ||

| Brinell HB | Rocknell HB | Min | Max | ||

| Soft Iron | 90 | 56 | P | -40 | 540 |

| Low C/S | 120 | 68 | S | -60 | 500 |

| SS410 | 170 | 86 | S410 | -40 | 850 |

| SS304 | 160 | 83 | S304 | -250 | 540 |

| SS316 | 160 | 83 | S316 | -200 | 815 |

| SS347 | 160 | 83 | S347 | -200 | 870 |

| 4-6%Cr,0.5% Mo, | 130 | 72 | F5 | -40 | 650 |

| Copper | 80 | - | C | -100 | 315 |

| Aluminum | 35 | - | A | -200 | 425 |

| Inconel 600 | 150 | 78 | Y | -100 | 1095 |

| Inconel 825 | 150 | 78 | W | -100 | 1095 |

| Monel 400 | 150 | 78 | M | -100 | 760 |

| Titanium | 215 | 77 | T | -200 | 540 |

| Nikel 200 | 110 | 58 | N | -200 | 760 |

| Hastelloy B2 | 230 | 121 | X1 | -100 | 1095 |

| Hastelloy C276 | 210 | 110 | X2 | -100 | 1095 |

The size of the metal lens gasket limit deviation:

| Name of size | Generation of no. | Limit deviation |

| Ring pad pitch diameter | P | + / - 0.18 |

| The width of the ring gasket | A | + 0.20 - 0 |

| The height of the ring gasket | H | + 0.20 - 0 |

| Metal lens mat bottom width | C | + 0.20 - 0 |

| 23 o Angle | Plus or minus 0.15 o | |

| Radius of ring gasket | R | + / - 0.4 |

| Metal lens mat all 23 o Angle of the plane, the surface roughness shall be no greater than 0.8 microns | ||

Metal lens gasket main performance parameters:

|

Coefficient of gasket |

m=5.50-6.50 |

| Gasket using pressure | <=32MPa |

| Gasket using temperature | - 196 oC to 1000 oC |

| Than the minimum preload pressure | y=126.6-182.8MPa |

Metal lens pad technology standards:

Can provide any size of standard and non-standard, including API 6 a, ASME B16.20, DIN 2693-67, JPI - 7-23-72 - s, DIN - 2696-1999 and other standards.

Domestic relevant standards:

JB/T 2777-1992 | PN16.0 ~ 32.0 MPa without aperture lens gasket

JB/T 2776-2010 | valve parts high-pressure lens pad

JB90-1959 type of flange sealing surface lens with metal gasket

Does the actual application condition is complex, the above parameters are for reference only do not make any guarantee is requested.Metal lens gasket material selection:

| material | Maximum hardness | mark | oC | ||

| Brinell HB | Rocknell HB | Min | Max | ||

| Soft Iron | 90 | 56 | P | -40 | 540 |

| Low C/S | 120 | 68 | S | -60 | 500 |

| SS410 | 170 | 86 | S410 | -40 | 850 |

| SS304 | 160 | 83 | S304 | -250 | 540 |

| SS316 | 160 | 83 | S316 | -200 | 815 |

| SS347 | 160 | 83 | S347 | -200 | 870 |

| 4-6%Cr,0.5% Mo, | 130 | 72 | F5 | -40 | 650 |

| Copper | 80 | - | C | -100 | 315 |

| Aluminum | 35 | - | A | -200 | 425 |

| Inconel 600 | 150 | 78 | Y | -100 | 1095 |

| Inconel 825 | 150 | 78 | W | -100 | 1095 |

| Monel 400 | 150 | 78 | M | -100 | 760 |

| Titanium | 215 | 77 | T | -200 | 540 |

| Nikel 200 | 110 | 58 | N | -200 | 760 |

| Hastelloy B2 | 230 | 121 | X1 | -100 | 1095 |

| Hastelloy C276 | 210 | 110 | X2 | -100 | 1095 |

The size of the metal lens gasket limit deviation:

| Name of size | Generation of no. | Limit deviation |

| Ring pad pitch diameter | P | + / - 0.18 |

| The width of the ring gasket | A | + 0.20 - 0 |

| The height of the ring gasket | H | + 0.20 - 0 |

| Metal lens mat bottom width | C | + 0.20 - 0 |

| 23 o Angle | Plus or minus 0.15 o | |

| Radius of ring gasket | R | + / - 0.4 |

| Metal lens mat all 23 o Angle of the plane, the surface roughness shall be no greater than 0.8 microns | ||

Metal lens gasket main performance parameters:

|

Coefficient of gasket |

m=5.50-6.50 |

| Gasket using pressure | <=32MPa |

| Gasket using temperature | - 196 oC to 1000 oC |

| Than the minimum preload pressure | y=126.6-182.8MPa |

Metal lens pad technology standards:

Can provide any size of standard and non-standard, including API 6 a, ASME B16.20, DIN 2693-67, JPI - 7-23-72 - s, DIN - 2696-1999 and other standards.

Domestic relevant standards:

JB/T 2777-1992 | PN16.0 ~ 32.0 MPa without aperture lens gasket

JB/T 2776-2010 | valve parts high-pressure lens pad

JB90-1959 type of flange sealing surface lens with metal gasket

Does the actual application condition is complex, the above parameters are for reference only do not make any guarantee is requested.